Chocolate production

Chocolate production according to Swiss chocolate quality

More than 3000 recipes, a wide range of carefully selected raw materials, and experience gained over almost 100 years: we offer all of this to our customers to turn their ideas and wishes for chocolate into reality. We have the necessary technical equipment to master all processes involved. Here we outline the six most important production stages from raw materials to finished chocolate.

Production stage 1

Mixing the chocolate raw materials

The ingredients are selected and weighed and kneaded in the mixer until a homogeneous paste-like consistency is achieved. The mixture is coarse and sandy in texture and the flavour is not yet fully developed.

Production stage 2

Rolling the paste-like mixture

The paste-like mixture is then ground in rolling mills using pressure and shearing forces. At the end of this process, the particles are smaller than 20 thousandths of a millimetre (< 20 µm).

Production stage 3

Conching the chocolate mass

After grinding, the chocolate mass is still in its original state. The individual ingredients are not yet combined with each other in terms of taste. The chocolate mass is stirred and kneaded in conches until any unwanted acids have evaporated and a very fine, smooth melting mass is produced.

Production stage 4

Pre-crystallisation

During the pre-crystallisation stage, the desired cocoa butter crystal formations are formed. To do this, the chocolate is cooled from 50°C to 28°C to allow all the fats to form crystals. Then, through targeted reheating to 30–32°C, the undesired low-melting crystals are melted away until only the required high-melting crystals remain in the liquid chocolate. During the subsequent solidification process, the cocoa butter crystals align in such a way that the solidified chocolate can be easily removed from the mould and exhibits the sought-after delicate melting texture and silky sheen.

Production stage 5

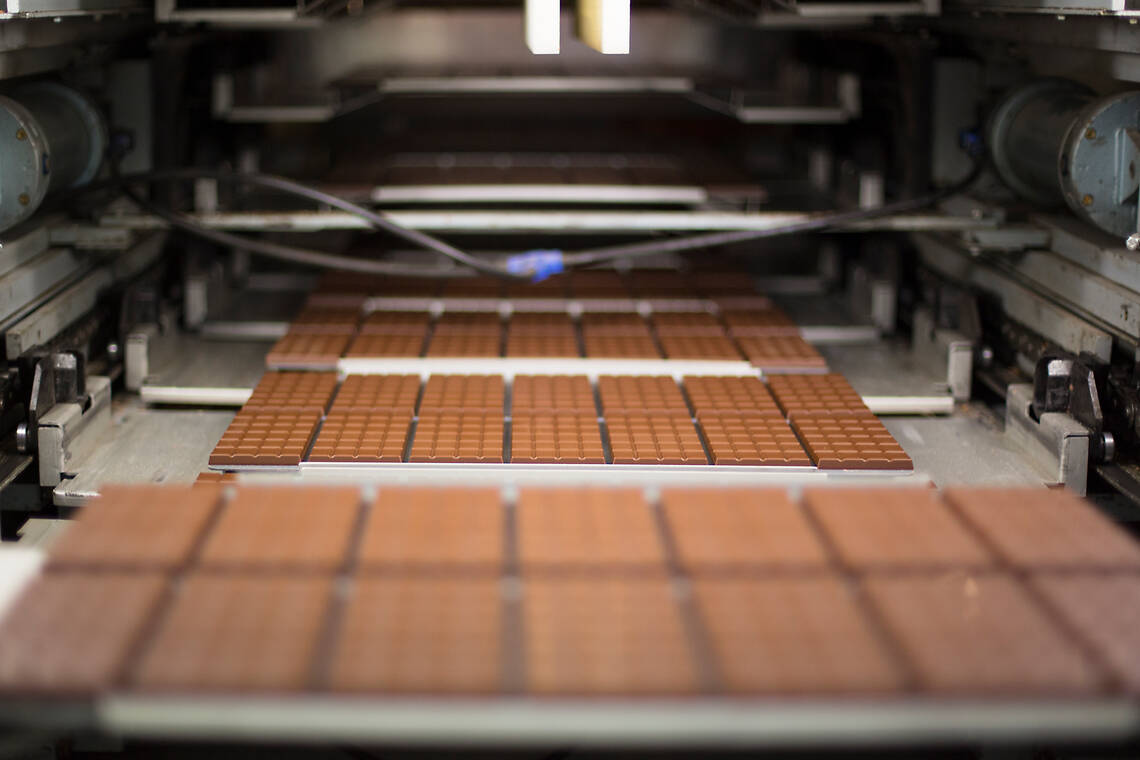

Moulding the chocolate

As for what shape the chocolate should finally take, there are almost no limits to what can be created. Chocolate bars of different weights, solid, filled or with extra ingredients such as nuts or sultanas – these are just some of the possibilities. There are also small chocolates such as napolitains, lunches, bars, branches and pralines with a wide variety of fillings. Seasonal items such as Easter bunnies or decorations for Christmas trees also feature in the range. Other popular lines include couvertures and semi-finished products for confectioners, patisseries and industrial enterprises.

Production stage 6

Packaging the chocolate

The finished chocolate products are packed in different materials on automated packaging machines.

Chocolate production – our locations

Explore our production facilities and visit us in one of our factory shops in Kreuzlingen or Ticino.